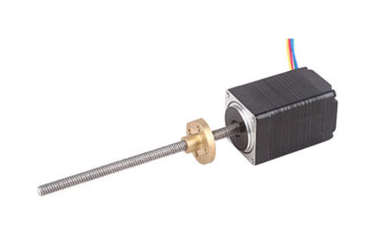

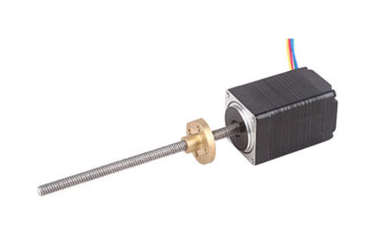

hybrid linear stepper motor is widely used in equipment machinery, such as machine tools, engraving machines, etc. need stepper motor drive, is a lot of machinery power drive equipment, hybrid linear stepper motor in many demanding fields have great use, the following is a brief introduction to its working principle.

Stepper motor from rotary motion to linear motion can be completed by several mechanical methods, including rack and pinion drives and belt and pulley drives and other mechanical coupling mechanisms. All of these designs require a variety of mechanical components. The most efficient way to accomplish this transformation is within the motor itself. The basic stepper motor consists of a magnetic rotor core that rotates by interacting with a pulsating stator electromagnetic field generated by the stator. Linear motors transform rotary motion into linear motion, and the precision with which this transformation is accomplished depends on the stepping angle of the rotor and the method chosen.

The precision of a linear motor using a thread depends on its pitch. A nut is mounted in the center of the rotor of the linear motor and a corresponding screw is engaged with this nut. In order for the screw to move axially, some method must be used to prevent the screw from turning with the rotor assembly. Since the screw rotation is constrained, the screw achieves linear motion as the rotor rotates. Either a fixed threaded shaft assembly inside the motor or an external threaded shaft with a nut that cannot rotate but can move freely in the axial direction is a typical way to achieve rotation restraint.

To simplify the design, it makes sense to implement a linear transformation inside the motor. This approach greatly simplifies the design and allows for precision linear movement in many applications using linear motors directly without the installation of external mechanical linkages. The original linear motor used a combination of a ball nut and a screw. The ball screw provided over 90% efficiency, while the trapezoidal thread provided only 20% to 70% efficiency, depending on the thread conditions. Although ball screws are an efficient method for converting rotary motion to linear motion, ball nuts are difficult to calibrate and are bulky and expensive. As a result, ball screws are not a practical solution in most applications. Most equipment designers are familiar with hybrid stepper motors based on linear motors. As with other devices it has its own strengths and limitations. Ease of design, compactness, lack of brushes, amazing mechanical advantages, practicality of design, and reliability are its inherent strengths, however, in some cases this linear motor cannot be used in certain equipment because it is not guaranteed to be durable without routine maintenance.

However, there are several ways to overcome this obstacle and make the

hybrid linear stepper motor highly durable and maintenance free. Due to the brushless design of the stepper motor, the only parts that generate wear are the rotor bearings and the threaded joints consisting of the lead screw/nut.

View More(Total0)Comment Lists