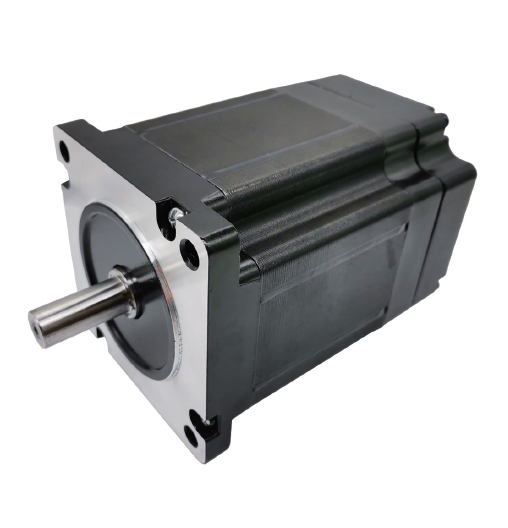

42mm brushless dc motor

Due to the commutation of the brush, the magnetic field generated by permanent magnet steel and the magnetic field generated by armature winding is always vertical during the operation of the motor, so as to produce the maximum torque and make the motor run. The operation principle of 48v brushless dc motor is under a magnetic pole with constant flux density distribution, the total amount of current flowing into the armature winding is ensured to be constant to produce constant torque, and the torque is only related to the magnitude of armature current.

The operation of 48v brushless dc motor also depends on the rotor position sensor to detect the rotor position signal, through the commutation drive circuit to drive the power switches connected with the armature winding on and off, so as to control the stator. When the winding is electrified, a rotating magnetic field is generated on the stator to drive the rotor to rotate. With the rotation of the rotor, the position sensor continuously sends out signals to change the electrified state of the armature so that the current direction in the conductor under the same magnetic pole remains unchanged. Therefore, a constant torque can be generated to make the 48v brushless dc motor run.

From the composition of 48v brushless dc motor, it is actually a closed-loop system composed of the motor body, electronic switch circuit, and rotor magnetic steel position sensor. The motor body has a star connection mode and angle connection mode. The inverter of the electronic switch circuit can adopt a half-bridge circuit or full-bridge circuit. Therefore, the different selection will produce different performance and cost of the motor. Here is a comparison.

(1) Winding utilization

Different from ordinary DC motor, the winding of 48v brushless dc motor is intermittent

Electrified. Properly increasing the utilization ratio of winding can increase the number of conductors electrified at the same time, decrease the resistance and improve efficiency. From this point of view, three-phase stator winding is better than four-phase, four-phase is better than five-phase, electronic switching line inverter using full-bridge control is better than half-bridge control.

(2) Torque fluctuation

The output torque ripple of a 48v brushless dc motor is larger than that of an ordinary DC motor, so we hope to reduce the torque ripple as much as possible. Generally, the more the number of phases, the smaller the torque ripple. Full bridge drive ratio half axle

The ripple of driving torque is small.

(3) Circuit cost

The more the number of phases, the more switches used in the driving circuit, the higher the cost. Full bridge drive uses twice as many switches as half-bridge drive, so it costs more. The structure of the multiphase motor is complex and the cost is high.

View More(Total0)Comment Lists